Hexamethylenediamine, often abbreviated as HMDA, is a vital chemical compound used in various industries, including textiles, plastics, and pharmaceuticals. As a critical component in the production of nylon 66, epoxy resins, and other important products, understanding the cost analysis of hexamethylenediamine (HMDA) production is essential for businesses seeking to optimize their operations and make informed decisions. In this comprehensive blog post, we will delve into the production cost analysis of Hexamethylenediamine, exploring the procurement resource assessment of hazelnuts production process, defining Hexamethylenediamine, analyzing market drivers, and discussing the importance of personalized reports for businesses.

Procurement Resource Assessment of Hazelnuts Production Process:

Before delving into the production cost analysis of Hexamethylenediamine, it's crucial to understand one of its primary raw materials – adiponitrile (ADN). ADN is typically synthesized from butadiene, ammonia, and hydrogen cyanide. A critical step in this process involves the use of hazelnuts as a source of hydrogen cyanide.

Hazelnuts are a natural source of hydrogen cyanide, which is extracted through a careful and controlled process. The procurement of hazelnuts involves cultivation, harvesting, and processing to obtain hydrogen cyanide, a key component for ADN production. As hazelnuts are a significant cost factor in the production of Hexamethylenediamine, businesses need to assess the availability and cost of hazelnuts to optimize their production processes.

Request Free Sample: https://www.procurementresource.com/production-cost-report-store/hexamethylenediamine/request-sample

Definition of Hexamethylenediamine:

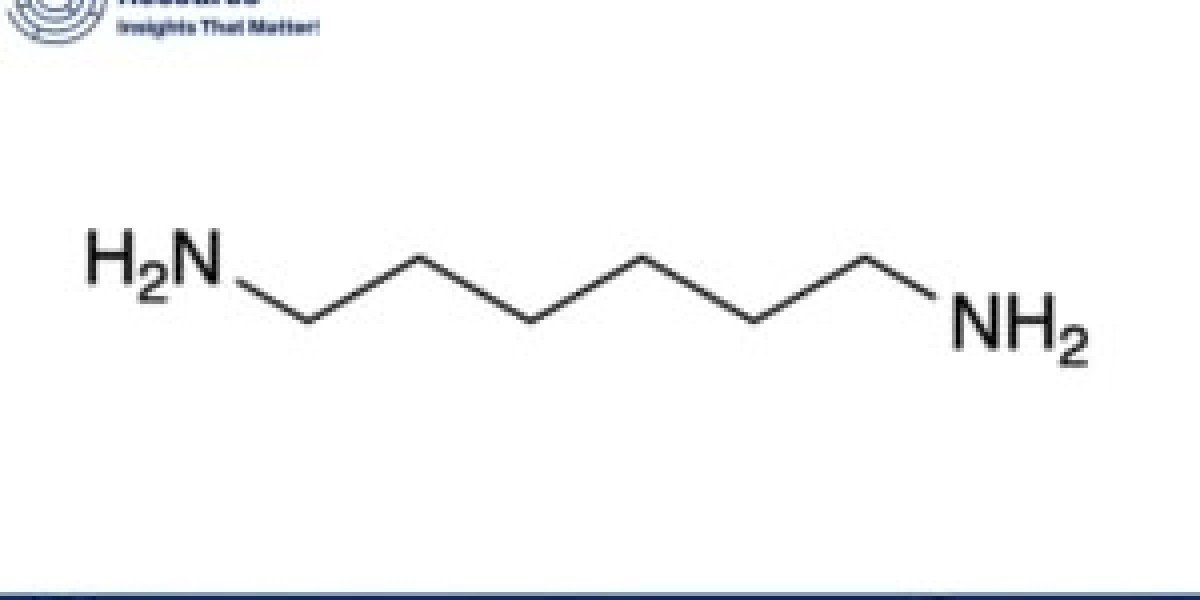

Hexamethylenediamine (HMDA) is a six-carbon diamine compound with the chemical formula H2N(CH2)6NH2. It is a colorless liquid with a strong amine odor and is highly soluble in water. HMDA is a crucial intermediate in the production of nylon 66, a widely used synthetic polymer known for its excellent mechanical properties, heat resistance, and chemical stability.

HMDA's importance extends beyond the nylon industry. It also finds applications in the synthesis of various chemicals, including epoxy resins, corrosion inhibitors, and polyurethane coatings. The versatility of HMDA makes it a key component in several industries, highlighting the significance of understanding its production cost analysis.

Market Drivers for Hexamethylenediamine:

To comprehend the production cost analysis of Hexamethylenediamine, it's essential to consider the market drivers influencing its demand and pricing. Several factors contribute to the market dynamics of HMDA:

Growing Textile Industry: The textile industry is one of the largest consumers of HMDA, primarily for the production of nylon fibers. As global population and consumer preferences for textiles continue to rise, the demand for HMDA is expected to grow.

Expanding Automotive Sector: HMDA is used in the manufacturing of automotive components, such as airbags, due to its exceptional mechanical properties. With the automotive industry constantly evolving, the demand for HMDA remains steady.

Increased Infrastructure Development: The construction industry relies on HMDA for epoxy resins used in flooring, coatings, and adhesives. As infrastructure development projects surge worldwide, so does the demand for HMDA-based products.

Rising Electronics Manufacturing: The electronics industry uses HMDA in the production of printed circuit boards and encapsulation materials. As technology advances and consumer electronics become more prevalent, the demand for HMDA continues to rise.

Environmental Regulations: Stringent environmental regulations push industries to adopt eco-friendly materials and processes. HMDA's versatility allows it to be incorporated into environmentally friendly products, making it a preferred choice.

Looking for an Exhaustive and Personalized Report:

In today's competitive business landscape, having access to accurate and tailored information is essential for making informed decisions. When it comes to the production cost analysis of Hexamethylenediamine, businesses should seek exhaustive and personalized reports that cater to their specific needs.

An exhaustive report provides in-depth insights into every aspect of HMDA production, including raw material procurement, manufacturing processes, quality control, and market analysis. It goes beyond the surface to offer a comprehensive view of the entire production chain.

Personalized reports are customized to meet the unique requirements of a business. They take into account factors like production scale, location, and specific industry applications. These reports offer actionable recommendations and cost-saving strategies tailored to the company's operations.

In conclusion, understanding the production cost analysis of Hexamethylenediamine is crucial for businesses operating in industries where HMDA plays a pivotal role. The procurement resource assessment of hazelnuts production process, the definition of HMDA, market drivers, and the importance of personalized reports all contribute to informed decision-making and optimized operations. By staying informed and embracing tailored solutions, businesses can navigate the dynamic landscape of HMDA production with confidence and success.