Fasteners are tiny things that are much overlooked in many industries, from construction to automobile manufacturing, that could make or break a project. Nuts, bolts, and other fasteners are unsung heroes from ancient times to join two or more things together with excellent craftsmanship. With increased industrial revolutions worldwide, the use of fasteners has risen rapidly.

It is the reason that the global industrial fasteners market is to grow at a CAGR of 4.6% from the current value of 95.46 billion dollars in 2023 up to 2030. It is only the largest industrial fastener manufacturers that contributes to its growth by providing high-quality fasteners to make many projects across industrial verticals successful. Also, they use HPDC or high pressure die casting to produce high-quality product forms.

In this article, let us discuss the most significant industrial fastener manufacturers in India and also all about high-pressure die casting to transform molten metal into solid parts with near-net-shapes within seconds.

What is high-pressure die casting?

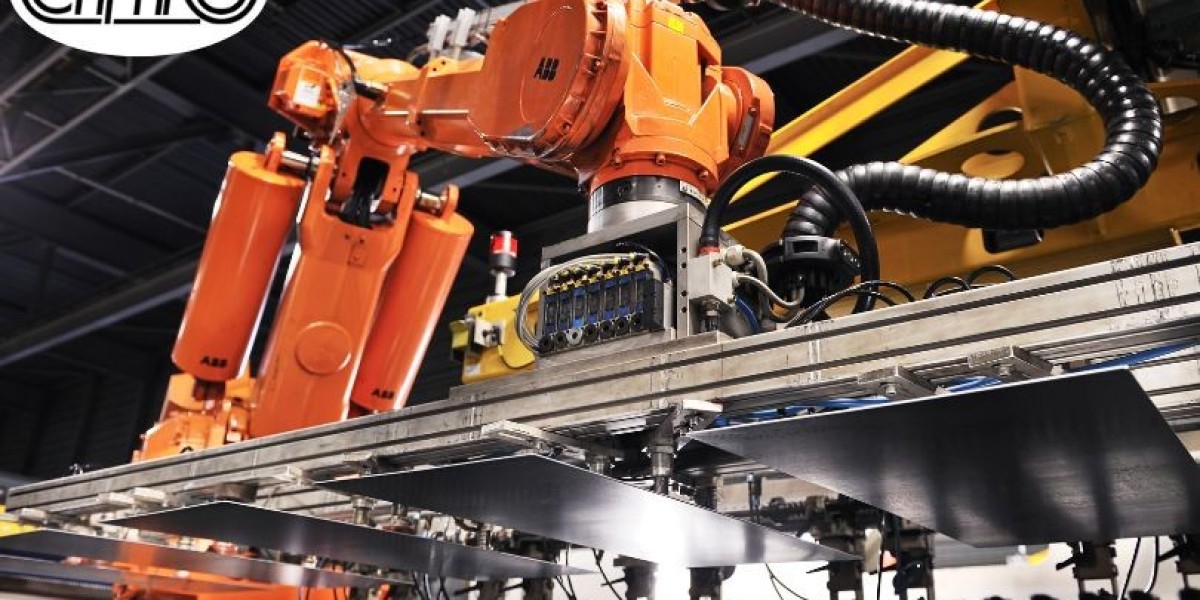

The demand for aluminium castings is rising worldwide in many industrial verticals from aerospace to automobile and other industries. It is because of the many features to make many hydraulic, electrical, light and other components. It is because of its many fantastic features like having high strength, less machining, low cost, outstanding finishes, etc. HPDC, or high pressure die casting, plays a critical part in making intricate aluminum castings and others to have all its benefits.

What are the benefits of high-pressure die casting?

Automotive, agricultural sector, aerospace, and other industries require light alloy parts with high efficiency and speed. Also, they need large parts with excellent surface finishes, superior uniformity, and good mechanical properties. And for parts with intricate shapes in a single piece with less machining but precise dimensional accuracy to eliminate the need for welding or assembly. High pressure die casting produces such intricate and complex parts in a single piece with close tolerances in a broader range of shapes than most other metal manufacturing techniques.

What are industrial fasteners and their applications?

Industrial fasteners are a massive group of devices and tools for joining pieces together semi-permanently and permanently. A few of the industrial fasteners include bolts, nuts, flanges, hinges, studs, screws, etc, proper in all industry verticals. Also, industrial fasteners are the unsung heroes for making many products, from cell phones to robotics, electrical motors, etc.

It is the reason that the global industrial fasteners market is to cross 100 billion dollars in a few years. Recent intensive technological developments help to make advanced and lightweight fasteners along with hybrid ones.

Which is the largest industrial fastener manufacturer in India?

India has many industrial fastener manufacturing companies that make high-quality nuts, bolts, and others using advanced technologies. The largest industrial fastener manufacturers in India is the market leader with years of experience making superior quality fasteners. Also, they make a wide range of special fasteners with high tensile standards. They supply fasteners to most of the top automotive OEM or original equipment manufacturers in India and abroad.

The largest fastener manufacturer in India makes and supplies industrial fasteners in huge quantities with high qualities and standard

Caparo started its fastener division in Chopanki, Rajasthan, in 2005, and it soon became the market leader in fastener technology in India. It is a 450-staffed facility with a 45,740 square meter area and has an 18,000 MT/PA capacity. Caparo India has specialist in-house manufacturing capability to make high tensile standards and special fasteners. Caparo also has a world-class OHSAS, IATF 16949, and ISO 14001-certified facility in Chennai with advanced machinery and equipment to make high pressure die-casting parts.