Computer Numerical Control machines are essential in the manufacturing industry. They help create durable goods like aircraft, artificial joints, and cars. They also help create specialized medical equipment. When shopping for a used CNC machine, consider its size and specifications. Also, check its compatibility with the software you use.

Machine Tools

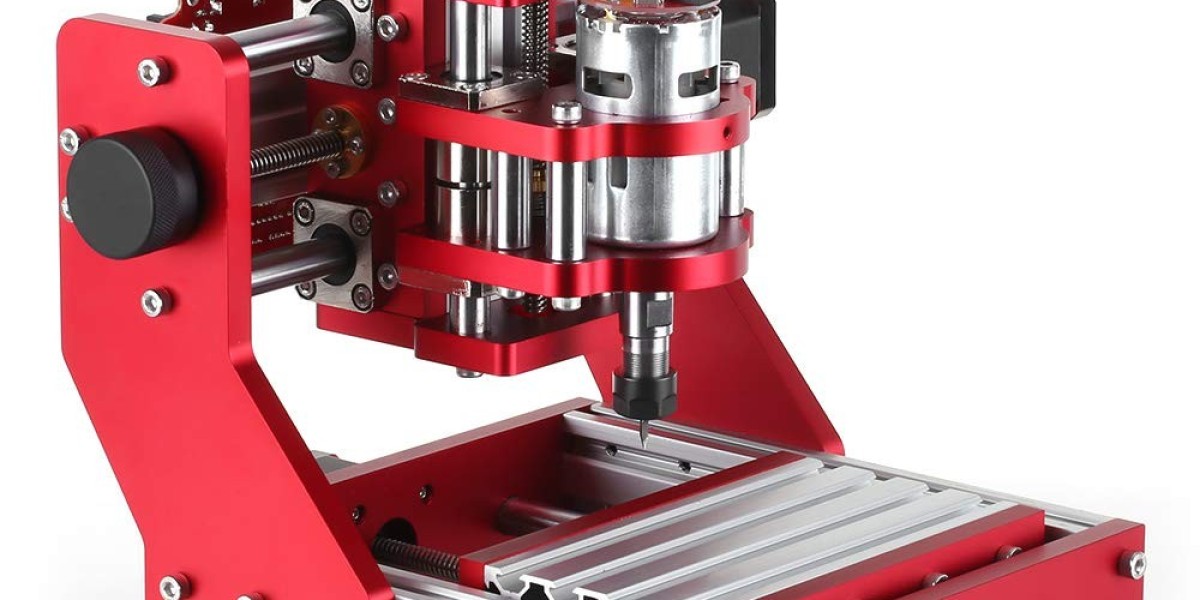

CNC machine tools provide an affordable, effective way for small businesses to expand their production capabilities. These tools are used to cut materials such as wood, plastic, metals, and composites to create precision parts for manufacturing applications. There are several types of CNC machines available for sale, including CNC mills, lathes, and grinders.

When selecting a CNC machine, it is important to consider the size and specifications of the machine. You also need to think about the number of axes. 2 axis machines move in two dimensions, while 3 axis machines move in three dimensions. Also, be sure to research the manufacturer’s warranty and service options. New machines typically come with a warranty, which provides peace of mind and protection against defects and malfunctions.

Machinery

Machinists and manufacturing technicians have to be very skilled to operate CNC machines because they can produce precise parts that can’t be produced manually. This precision is crucial for producing durable goods like aircraft, railways and automobiles. When buying a used CNC machine, it’s important to consider the size and specifications of the device. Make sure that the machine meets your production requirements and can be upgraded when necessary. It is also essential to check the availability of support and spare parts for the machine you plan to purchase.

New machines typically come with a warranty, which can provide peace of mind and protection against malfunction or defects. Additionally, new machines are often available with a variety of customization options that can help tailor the equipment to your business’s specific needs. This includes varying the worktable size, adding additional tooling, or choosing a different type of control system. You may also be able to choose between a desktop or floor-standing model.

Equipment

A wide variety of CNC equipment is available for sale, ranging from a basic router to an advanced mill. The type of machine you choose will depend on your needs and budget. A standard router operates on 3-axis coordinate and cuts shapes from wood or metal sheets. You can also purchase 4- and 5-axis machines for complex jobs.

Other types of used cnc equipment for sale include plasma cutters and a CNC lathe. The former uses a powerful laser to cut materials while the latter turns a piece of metal into a shape with a spinning blade.

Regardless of the type of machine you select, it’s important to inspect it carefully for signs of wear and tear and potential rust or damage. Make sure the brand you choose offers support and spare parts. Also, look into the software, working area size, automation features, and other factors that could affect your production process. If needed, interested individuals can click here or visit our official website in order to know about buy used cnc machines .

Used CNC Machines

CNC machines enable manufacturers to automate a variety of processes. They are commonly used by professionals in the fabrication industry and even by hobbyists who take a hands-on approach to their work. Machinists are responsible for stocking materials, performing maintenance and evaluating the final products to ensure they meet standards. They read blueprints that are translated into code the machine understands using CAD software.

The machine then carries out the instructions with precision. This allows for a higher quality product with less waste and lower energy consumption. The result is a more cost-effective manufacturing process that can be scaled to larger sizes for increased production.