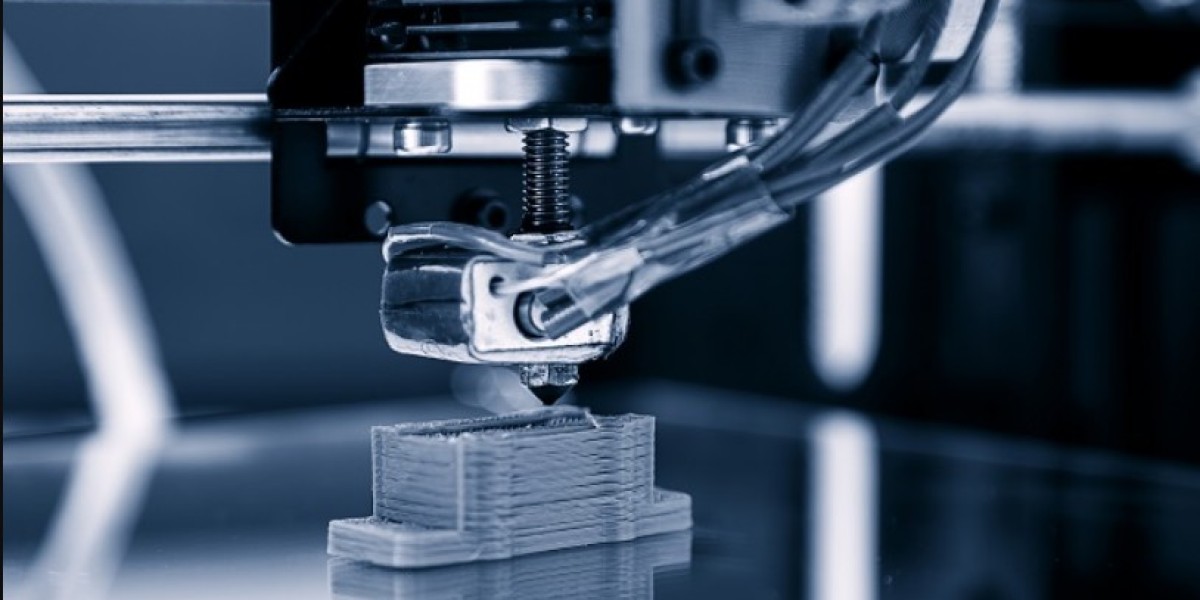

3D printing technology holds enormous potential to revolutionize our world. It shortens time from design to production, shifts power away from manufacturers and allows designers to design radically new architecture at fractions of traditional manufacturing costs.

Additive manufacturing can bring many advantages to various industries. This white paper explores its many uses for improving products and processes within businesses.

How 3D Printing Will Change the World

3D printing holds immense promise to transform how products are manufactured, offering increased resource efficiency, reduced energy use and an eco-friendlier production process.

Additionally, additive manufacturing technology can reduce waste while cutting manufacturing costs and lead times. Furthermore, it offers greater versatility than traditional processes for producing an array of parts for products with both functional and aesthetic needs.

Winsun, a Chinese company, has developed technology to build homes out of recycled am materials at significantly reduced costs, potentially making housing affordable to more people around the world.

Construction safety can also help construction workers be safer on the jobsite, saving employers both time and money in reduced injuries as well as increasing building durability - meaning fewer repairs or replacements will be needed over time.

Industrial Applications

3D printing manufacturing aids such as jigs, gauges and fixtures is becoming a vital tool in various industries. They can serve as fast prototypes for testing purposes or produce customized parts in smaller runs.

3D printing technology has revolutionized the automotive industry. 3D printers can replace costly tooling such as moulds CNC milled by CNC, which often require multiple iterations before reaching their final design - saving both money and reducing waste.

Construction companies have also seen 3D printing become an increasing tool in building. Not only can 3d printing powders save them both time and money, it makes creating buildings with greater durability simpler.

These benefits make construction projects more profitable for construction companies and clients alike, according to a recent study which demonstrated that 3D printing technologies have the capacity to reduce construction costs by 50-70% while simultaneously cutting labor costs up to 80%.

Medical Applications

3D printing technology has quickly made waves in healthcare, as its applications improve surgical techniques, streamline prosthetics and implants production, as well as manufacture medications, skin tissues and organs on demand.

Utilizing 3D printers to create physical models tailored specifically to each patient can enhance surgical outcomes while decreasing costs. Furthermore, such models help physicians explain surgery to their patients beforehand and reduce any anxiety they might be feeling about the process.

Powder bed fusion and material jetting technologies are popular methods used to produce these models, which serve as an invaluable way of teaching students anatomy and medical procedures before performing them on real patients.

One student at the University of Waikato in New Zealand wanted to use 3D printing to build a model of a tumor that she could use for testing drugs for breast cancer, learning more about cancer cells and their behavior, which would enable doctors to provide better treatment to their patients.

Consumer Applications

Powder 3D Printing technology offers numerous consumer applications, from home-built housing for electronics to DIY projects. However, its most practical use lies in providing customized products tailored specifically to consumer preferences and needs.

One such 3D printed prostheses designed to assist those who have experienced limb loss is 20% cheaper and more comfortable to wear than traditional molded versions.

3D printers are being increasingly utilized to fabricate artificial limbs for pets, not only reducing or eliminating the need for costly prostheses but also increasing their quality of life by enabling them to participate in rewarding activities again.

3D printing has the potential to change our world in numerous ways. As more products can be tailored specifically for us, 3D printing will continue its expansion and impact.