Introduction

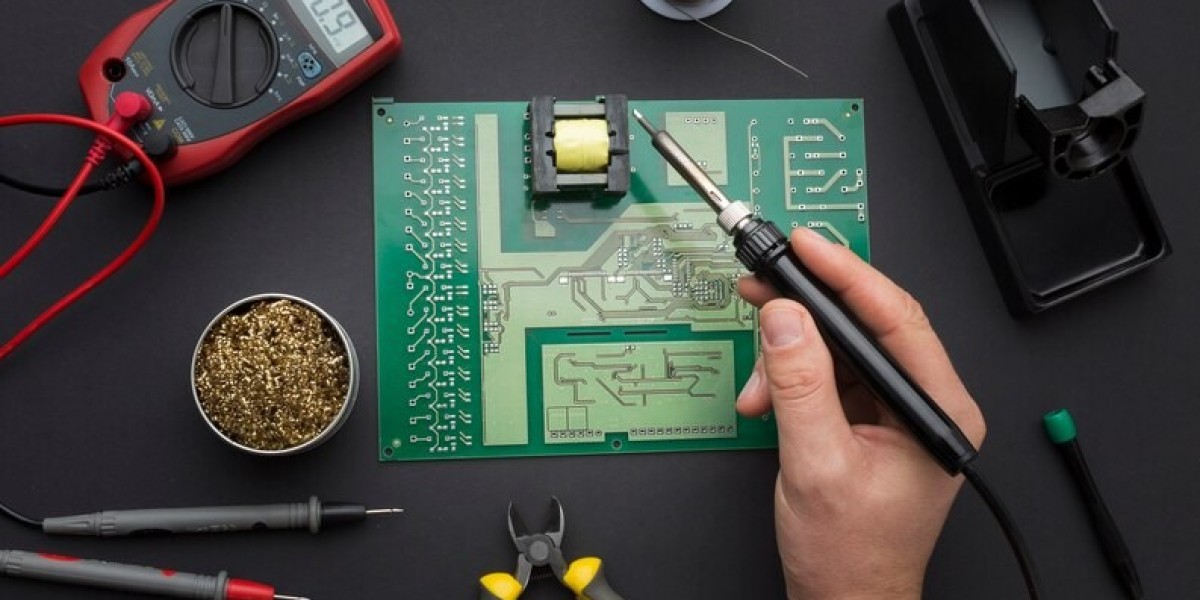

In today's fast-paced world, electronics play a crucial role in our daily lives. From smartphones to smart home devices, we rely on technology to keep us connected and make our lives easier. Behind the sleek and functional designs of these electronic devices lies a complex network of components working together, and at the heart of it all is the Printed Circuit Board (PCB). PCBs are the foundation of electronic devices, providing the electrical connections between components and ensuring their proper functioning.

The Importance of PCB Manufacturing

PCB manufacturing is a critical step in the electronics production process. The quality and reliability of PCBs directly impact the performance and durability of electronic devices. As technology continues to advance rapidly, the demand for smaller, more efficient, and more reliable PCBs is on the rise. To meet this demand, PCB manufacturing services have evolved to streamline the production process and deliver high-quality PCBs in a timely manner.

Advanced PCB Manufacturing Techniques

High-Density Interconnect (HDI) Technology

HDI technology is revolutionizing the PCB manufacturing industry. With the increasing demand for smaller and more compact electronic devices, traditional PCB manufacturing techniques are no longer sufficient. HDI technology allows for the creation of PCBs with higher circuit density, enabling the integration of more components in a smaller space. This not only saves valuable real estate in electronic devices but also improves signal integrity and reduces noise interference.

Automated Assembly

Gone are the days of manual soldering and component placement. Automated assembly has transformed the PCB manufacturing process, offering higher precision, faster production times, and improved consistency. Advanced robotic systems are now used to accurately place components on the PCB, ensuring proper alignment and soldering. This not only reduces the risk of human error but also increases production efficiency and reduces costs.

3D Printing

While 3D printing has gained significant popularity in various industries, its application in PCB manufacturing is a game-changer. 3D printing allows for the creation of complex and customized PCB designs with intricate geometries that were previously impossible to achieve. This opens up new possibilities for design innovation and optimization, allowing engineers to create PCBs that are tailored to specific applications and requirements.

Benefits of Streamlining PCB Manufacturing

By adopting the latest PCB manufacturing services and techniques, electronics manufacturers can reap numerous benefits:

- Faster Time to Market: Streamlined PCB manufacturing processes enable faster production times, allowing manufacturers to bring their products to market more quickly and stay ahead of the competition.

- Improved Quality and Reliability: Advanced manufacturing techniques ensure the production of high-quality, reliable PCBs, reducing the risk of product failures and customer dissatisfaction.

- Cost Savings: Automated assembly and efficient production processes help reduce manufacturing costs, making PCBs more affordable without compromising on quality.

- Design Flexibility: With 3D printing and HDI technology, designers have greater flexibility in creating customized PCBs that meet specific design requirements and performance criteria.

Conclusion

The evolution of PCB manufacturing services has transformed the electronics industry, enabling the production of smaller, more efficient, and more reliable electronic devices. By streamlining the PCB manufacturing process and adopting advanced techniques, manufacturers can benefit from faster production times, improved quality, cost savings, and design flexibility. As technology continues to advance, we can expect even more innovations in PCB manufacturing, further driving the progress of the electronics industry.