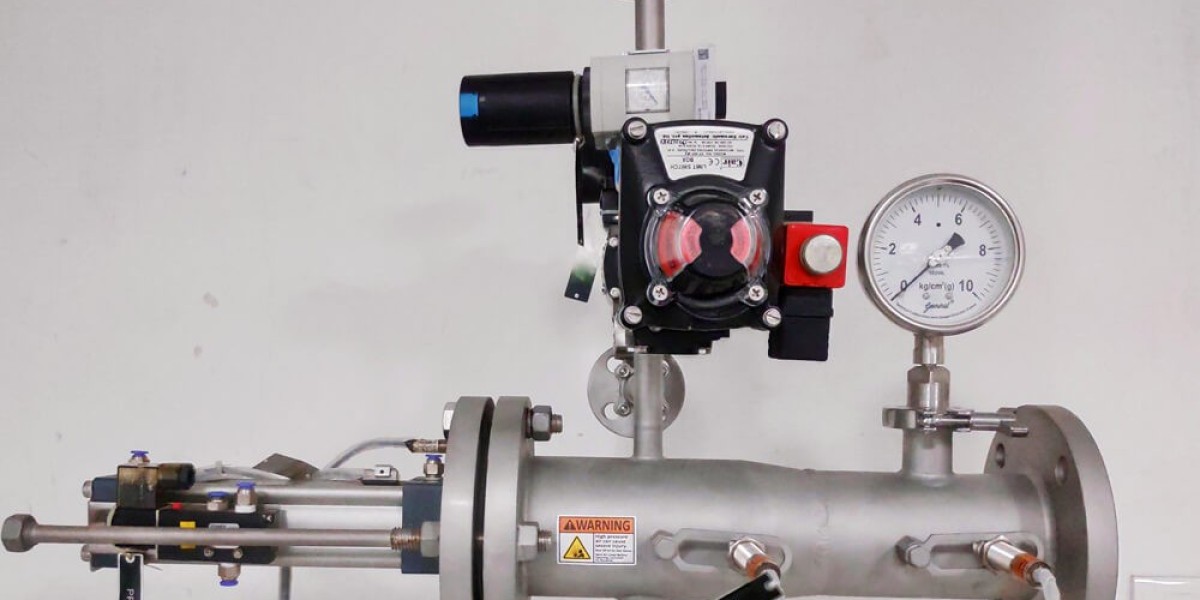

Industrial pigging systems are a versatile and efficient way to clean and maintain pipelines, tanks, and other process equipment. They can also be used to recover product and reduce waste. Industrial pigging systems can significantly increase productivity in a variety of industries, including:

Food and beverage: Pigging systems can be used to clean pipelines and tanks used for processing food and beverages. This helps to improve food safety and quality, while also reducing downtime and cleaning costs.

Oil and gas: Pigging systems are used to clean pipelines used to transport oil and gas. This helps to prevent the buildup of deposits and corrosion, which can lead to pipeline failures and environmental damage.

Chemical processing: Pigging systems are used to clean pipelines and tanks used for processing chemicals. This helps to improve product quality and reduce the risk of contamination.

Pharmaceutical: Pigging systems are used to clean pipelines and tanks used for manufacturing pharmaceuticals. This helps to ensure product purity and meet strict regulatory requirements.

How Industrial Pigging Systems Increase Productivity

Industrial pigging systems can increase productivity in a number of ways, including:

Reduced downtime: Pigging systems can significantly reduce the downtime required for cleaning and maintenance. This is because pigging systems can clean pipelines and tanks more quickly and efficiently than traditional methods, such as manual cleaning or flushing.

Improved product recovery: Pigging systems can help to improve product recovery by removing residual product from pipelines and tanks. This can lead to significant cost savings, especially in industries with high-value products.

Reduced waste: Pigging systems can help to reduce waste by preventing product contamination and reducing the need for cleaning chemicals. This can lead to environmental benefits and cost savings.

Improved efficiency: Pigging systems can help to improve the overall efficiency of production processes by streamlining cleaning and maintenance procedures. This can lead to increased throughput and output.

Tips for Increasing Productivity with Industrial Pigging Systems

There are a number of things that businesses can do to increase productivity with industrial pigging systems, including:

Choose the right pigging system for the application: There are a variety of different pigging systems available, each with its own advantages and disadvantages. It is important to choose a system that is right for the specific application.

Implement proper operating procedures: It is important to develop and implement proper operating procedures for the pigging system. This will help to ensure that the system is used safely and efficiently.

Maintain the pigging system regularly: It is important to maintain the pigging system regularly to ensure that it is in good working condition. This will help to prevent downtime and problems.

Train employees on the pigging system: It is important to train employees on how to use the pigging system safely and efficiently. This will help to reduce the risk of accidents and ensure that the system is used properly.

Conclusion

Industrial pigging systems can be a valuable tool for increasing productivity in a variety of industries. By implementing a pigging system and following the tips above, businesses can reap the many benefits of increased efficiency, reduced downtime, and improved product quality.